in the late nineteenth century billiard balls were the fourth most important use of ivory, after knife handles, piano keys and combs, but they required the largest and highest quality tusks. nearly 50 tons of ivory were made into billiard balls each year for the european and american markets. consumption had exhausted supplies almost entirely, so that by 1890 each ball cost the equivalent of $350 today. one american billiard manufacturer sponsored a competition to find an ivory substitute, but when john hyatt discovered the application of celluloid in 1868 he decided to found his own billiard ball manufacturing company: the albany billiard ball company, which also became america’s first plastics manufacturer. although celluloid is not technically synthetic – it is made from camphor and cellulose – it was the first commercialized thermoplastic. you can still find the archives of hyatt’s company on-line, with images from the manufacture of his paper-and-celluloid balls which revolutionized not only billiard balls manufacturing but the way luxury and non-luxury goods are made to this day, from plastic.

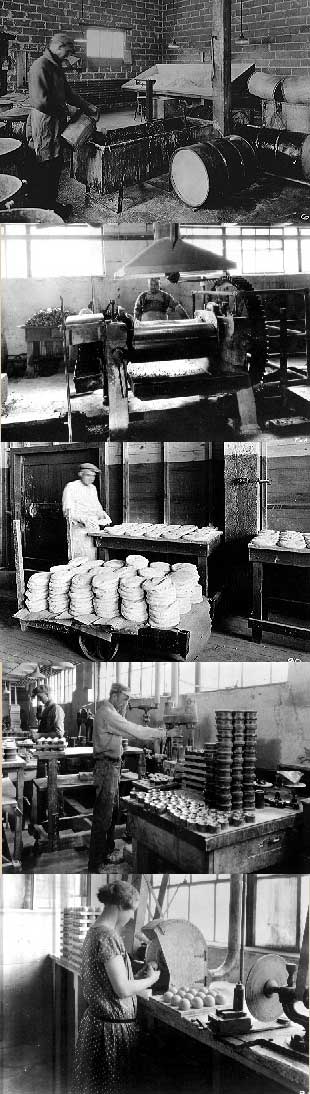

from top to bottom:

1)Celluloid scrap is sprinkled with solvents to plasticize it preparatory to mixing it with fillers, and is set aside to become uniformly plastic.

2) The plastic celluloid is mixed with the filler on ordinary mixing rolls. The resulting stock is formed into sheets.

3) While in a warm plastic state the product is mixed with filler and formed into pats which when cold, are hard and brittle. They are spread on the table for cooling and hardening before going into the dryer.

4) Rough balls are knocked out of molds in a hydraulic press.

5) In the final steps, balls are sanded and polished. The manufacturing process is completed with the buffing on a special buffing wheel.