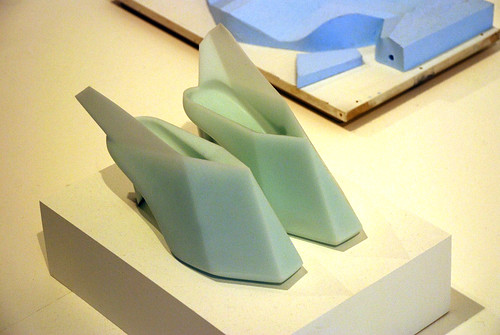

Ten Bhomer‘s ‘Rotational Moulded Shoe’ is an anti-craft exploration that seeks to replace the manual process of shoe-making with a machine. A plastic shank is placed inside a mold with rubber resin, and as the mold is continuously rotated the rubber hardens into a shell akin to the way rubber duckies are made. While seemingly no different from the Puma Injex, these shoes are formally unique and unrelated to traditional paradigms. Perhaps a more worthwhile exploration will be to discover ways to expand traditional craft while producing attractive and cutting-edge designs that are as desirable as these futuristic heels but vastly more sustainable.

From the exhibit placard at the London Design Museum:

Trained as a product designer, Ten Bhomer uses her skills to explore and create footwear in an industrial production process as opposed to the traditions of a cobbler. The provesses are informed by both material and applications and resulting in shoes that no longer live within preconceived ideas of what shoes ought to look and feel like. Rotational Moulded Shoe uses rotational moudling as a footwear production process and has been developed for the installation ‘After Hours’ at the Krannert Art mUseum in the US. Rotational moudling is a process in which a negative mould is filled with a small amount of liquid and as the mould starts to rotate, this material solidifies against the inner walls of the mould, forming a shell, a hollow form. As this technique has never been attempted for shoe making in the past, a special rotation moulding machine has also been designed and made to achieve the desired effect.

One Comment